News

-

Every mile counts: ZOUTMAN chooses green transport

From our sites in Roeselare and Ghent, we deliver up to 450,000 tonnes of sea salt annually to customers in more than sixty countries. By shifting to rail and inland shipping, we’re consciously moving towards a more sustainable logistics model.

Read more -

Participation PLMA - Private Label Manufacturers Association 2025

We’ll be at PLMA in Amsterdam on Tuesday 20 and Wednesday 21 May, the annual international trade show for private label.

Read more -

Participation Aquatech 2025: discover SOFT-SEL® and POOLSEL®

From Tuesday 11 March to Friday 14 March, you will find us at Aquatech in Amsterdam, the world's leading trade fair for process, drinking & waste water.

Read more -

New packaging, same quality: MARSEL® 1 kg coarse & fine sea salt

The MARSEL® 1 kg bag has been updated. 100% recyclable, more practical to use & better visibility on shop shelves thanks to the standing bag design.

Read more -

Participation Food Ingredients Europe 2024

Our experts will be present at the food trade fair Food Ingredients Europe in Frankfurt from Tuesday 19 November to Thursday 21 November.

Read more -

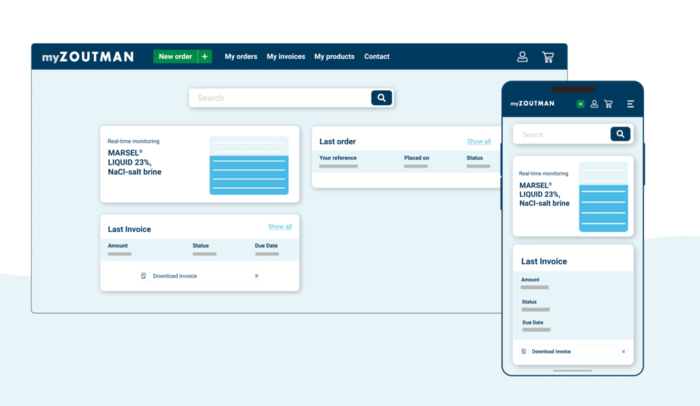

ZOUTMAN launches MyZOUTMAN customer portal

As a customer of ZOUTMAN, you can now utilize the MyZOUTMAN customer portal. With a personal login, you'll find all order information at your fingertips.

Read more -

POOLSEL® swimming pool salt has a new design

POOLSEL® swimming pool salt gets a refreshing makeover! The new design incorporates the benefits and is now available in more languages.

Read more -

ZOUTMAN is building a new production facility to keep up with global demand for sea salt

ZOUTMAN is building a 64.5m high production tower in Ghent in response to the global demand for sea salt, and will deliver an extra 150,000 tons of production per year.

Read more -

MARSEL® and PSOTRAMIL® are now also NATRUE-certified

MARSEL® and PSOTRAMIL® are now NATRUE-certified. Our sea salt is extracted sustainably and bears its international recognition with pride.

Read more -

ZOUTMAN launches MARSEL® and SOFT-SEL® in liquid form

ZOUTMAN innovates with MARSEL® and SOFT-SEL® in liquid form, making production processes easier and more ergonomic.

Read more -

ZOUTMAN responds to growing demand for sea salt

To meet the growing global demand for high-quality sea salt, ZOUTMAN is expanding its production facility in Roeselare.

Read more -

New biocide regulation effects salt

With new EU biocide rules, swimming pool salt must have Belgian approval. Only salt with a legal notification number is permitted.

Read more

- 1

- Next